Services ...

![]()

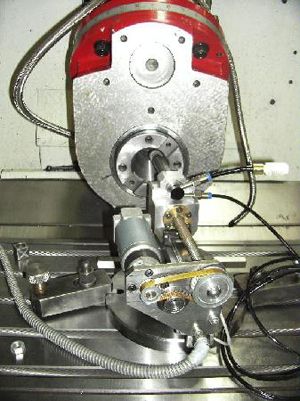

We provide you with services ranging from maintenance-related services to services associated with the retro-fitting of manual and CNC-controlled milling machines machining centres. You might be confronted by the following question: "Should we overhaul the machine or just buy a new one?”

We can also provide you with the right concept for your machine tool. Our expertise is at your service...Repairs ... We guarantee that you shall receive extensive consultations and support services when your cutting machine tools or CNC control systems are being repaired or serviced!

|

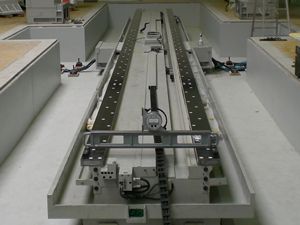

Maintenance ... Several people are well-acquainted with the problem: A machine stoppages that follows the emergence of a defect. The damage emerges after a deficient or inappropriate maintenance operation. Unsatisfactory or deficient maintenance often causes cost-intensive damage to machine tools. We develop a tailor-made maintenance schedule for your machine, which features

Long years of experience demonstrate that preventive maintenance is the most economical option. |

|

Installation and activation ... Installing and activating machine tools are activities that take up a lot of time. These activities are massively dependent on the capabilities of the commissioning staff. Our long-standing experience guarantees a competent and timely assembly process that possible amount of customer value.

... up |